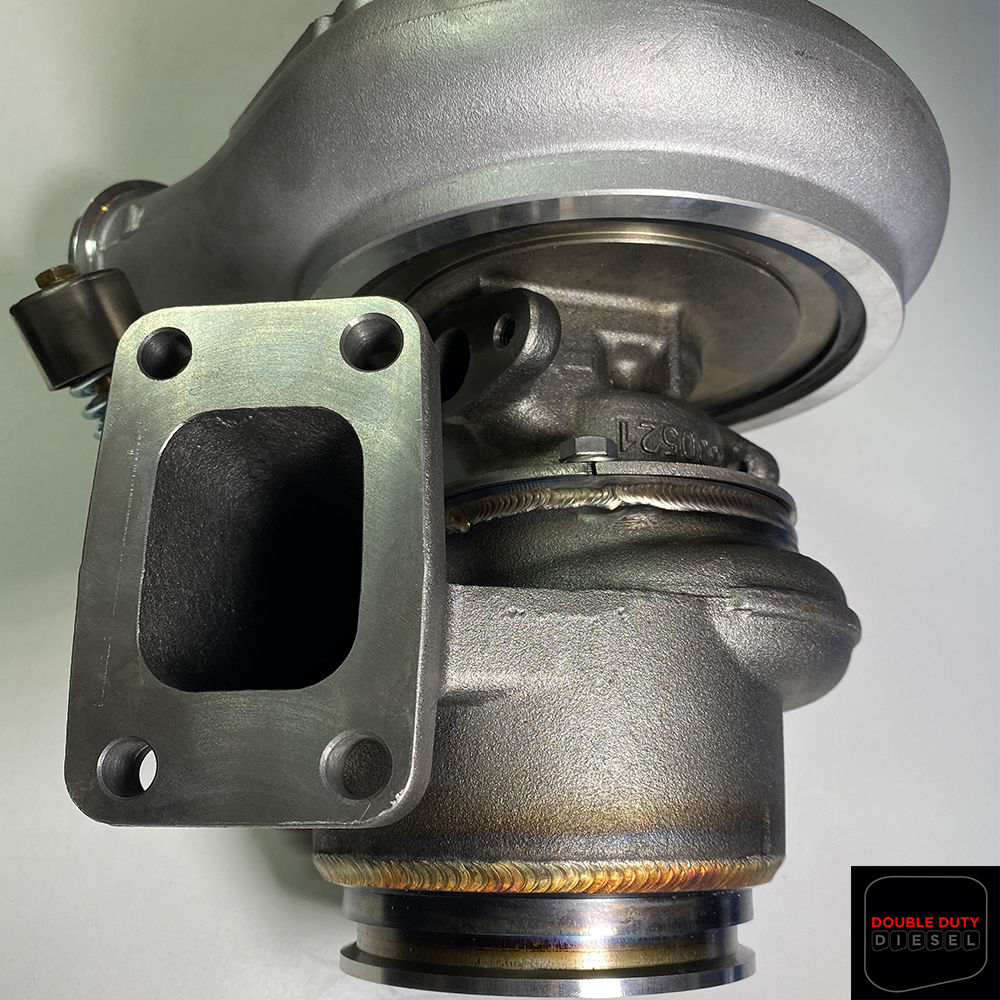

This is the Hx super 9 kit.

It is the highest hp capacity quickest spooling turbo that still uses a t3 turbine inlet foot.

On the chassis dyno it made more torque per rpm with the 60mm compressor wheel then the famous k27 turbo which is rated to 400 whp.

Turbine outlet has been modified to fit Hx40 down pipes.

We use the hx40 as the standard because it is so popular, easy to get for the end user, the pre made down pipes fit, and is the lowest cost pre made down pipe.

60mm billet compressor wheel supports 600 whp.

62mm compressor wheel supports 700 whp

67 compressor wheel supports 800 whp

These numbers are plus or minus 50 whp, we do the dyno testing on our own dynojet chassis dyno but not all dyno’s are calibrated equally and ours tends to read on the low side/make us work for every rwhp.

It is critical to select the proper sized compressor wheel for your application.

The 60mm is the best for tow/600 whp trucks. It is a absolute monster of a turbo at 50 psi on a 5.9L motor we rate the compressor to 3500 rpms.

The 62mm is a good compromise for tow/hp with a 700 whp capacity and a rpm bump to 3700 rpms at 50 psi. It does loose some torque in the low to mid vs the 60mm compressor but when a little more running room is needed rpm wise and or capacity it is a great choice.

Then the big bad 67mm max effort compressor wheel. This compressor due to having the most surface area has the highest blade loading and as such the slowest spooling unit. Still faster spooling then the famous 62/68/.70 borg sxe turbo. Just slower then our 60 and 62mm compressors. With a whp capacity of 800 whp 4000 rpms at 50 psi it is a absolute monster with the widest rev range out of the three compressor sizes. We usually use this turbo for 600 whp verified minimum motors to properly drive this monster.

67mm turbine wheel to support up to a sustained 60 psi. ( we do test to much higher pressures then 50 psi, we have pushed upwards of 76 psi gauge verified, but for longevity and reliability we recommend 50 psi)

We only use the 67mm turbine wheel on all of our turbo chargers due to through testing both on the dyno and in competition it produces the most power, best response, and best egt control out of all the turbine wheels and turbos we have tried.

Comes with our spring gate to net the boost pressure I like to see out of these turbos.

That being said your own boost pressure will vary based on fueling, tuning, and elevation. If unsure of what’s safe we recommend a maximum of 50 psi/4000 rpms for reliability.

Turbos and products run in competition on a 13mm p7100 powered pull truck that compete as well as other heavy haul and high powered street rigs.

With the spring gate on some applications, slight modifications to the oil drain may be needed, nothing extreme and has to be done with most aftermarket turbos anyways so regardless at some point in your performance adventures the oil drain tube will need re work.

Oem 4” inlet

Oem hx compressor outlet.

Oem turbo oil inlet/outlet.

Turbo is set up for flipped OEM manifold (45 degrees up)

Spring gate available for other turbo setup options!!

Exhaust manifold gasket and Turbo drain gasket included

| Weight | 13 kg |

|---|---|

| Compressor size | 60mm, 62mm, 67mm |

You must be logged in to post a review.

Reviews

There are no reviews yet.